|

|

| A

Real Sport Engine

|

|

The Type R has the same 2.0L DOHC

I-VTEC engine as powered in the Integra IS model. New engine series DOHC i-VTEC

of Honda is intelligent engine which raises torque, mpg, and releases low

emission exhaust gas. However, certain components such as the cylinder heads

have been exclusively designed for this version of the Type R. Honda has paid

special attention to the casting process for these parts that gives a

|

big improvement in the

efficiency of intake and exhaust cycles. The extra efficiency has meant a more

aerodynamic effect in the overall combustion process and thus a dramatic

improvement in the engine power output and performance of the Type R.

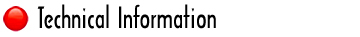

[Optimum Gear

Shiftpoint Curve]

|

|

|

|

A Light-weight Forged

Chrome-Molybdenum Steel Flywheel

|

| A super-light flywheel made of

chrome-molybdenum steel gives the Type R a smoother power transition between

the K20A engine and the Type-R close-ratio 6-speed transmission. The lightened

flywheel improves both the feel and performance of the engine. It gives an

instant response at any sudden throttle, when acceleration is demanded at any

time as driver steps on the metal pedal. It reduces about 0.3 seconds in

accelerating from 0 to 100 km/h, which equals to a reduction of 50 kg in the

car weight.

|

|

|

|

The newest safe structure, a RVS

selection control system

|

|

The DC5 uses a

speed-sensored solenoid-type selection lock, RVS selection control system, same

system adopted by NSX. When vehicle speed exceeds 20 km/h (~12 mph), the

solenoid will be set to ON, a cam will be locked and the selection operation to

a reverse gear becomes impossible, so a shift mistake can be prevented.

|

|

|

|

A multi-corn synchronization

mechanism is adopted as the first in the world in a 2-litre classes

|

| In order to reduce the load at the

time of shift operation, it is effective to raise synchronization capacity. The

DC5 adapts multi-corn synchronization, using triple corn for 1st and 2nd gear

and double corn for 3rd to 6th gears. About 10% increase in diameter size was

attained simultaneously. Shift load decreases now and pleasant operation can be

enjoyed with a crunching sound. Moreover the rubber of the joint portion of a

gearshift has a stopper structure which gives a rigid combination. The shift

load between 2nd and 3rd gear has acquired about 5 kgf(s), a lighter value

comparing to 7 kgf(s) by Toyota Celica 6MT and 6 kgf(s) by S2000. Although it

was common that the shift load of a sports car is heavy, by Type R, such a

concept is swept away by adoption of a multi-corn synchronization. It is

decided invigoratingly lightly. The so-called "sports car which does not sweat"

was made.

|

|

|

|

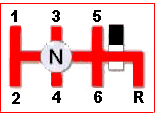

Variable path Exhaust pipes

|

|

The Type-R equips a new exhaust

muffler that is constructed of variable pipes. The design can change silence

priority by leading exhaust gas flow to variable paths with a silencer. At a

low rpm region, silence priority becomes first. Sound is reduced and air

current is reduced at the same time. As engine speed reaches near the 5,000

rpm, higher exhaust gas output becomes the priority that desires less back

pressure. This design bumps up an extra 4 hp and 0.8 kg-m, than the predecessor

model. Comparing at 8,000 rpm, about 1/3 of

backpressure remains, therefore a large improvement

|

| in the power output was

achieved at the dual e-type exhaust pipe. Moreover, sport nature was emphasized

by the adoption of a larger diameter finish.

|

|

|

|

A Clutch Start System

|

| The DC5 has adopted the clutch start

system as safety is measured from the time of engine starting. If the clutch

pedal is not stepped on, the protection does not allow engine to start into

operation.

|

|

|

|

Reducing body inertia moment

|

| The front lower arm using aluminum

forged material allows an effective weight reduction, each decreased by 1.6kg.

The DC5 front and rear-end body is also strengthened by employing aluminum

material for the bumper beam and floor crossing beam. A rear brake caliper is

also aluminized. From the center of gravity, lightened components reduce the

overall inertia moment as much as possible. The handling response is increased.

|

|

|

|

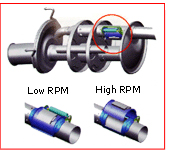

An Integration of a 4-port

Brembo Brake System into the Type-R

|

|

The Type-R makes use of a Brembo

4-port brake system for the front. Brembo is well-known for its performance

braking systems for track racing and widely used on standard exotic sports cars

as their Original Equipment Manufacturer (OEM). By the physics of objects

during deceleration, it explains that a higher percent of the vehicle weight is

distributed towards the front in relative to the rear. As Type-R has a

front-mounted engine design, a higher front-to-rear weight distribution is

greatly compensated by the excellent Brembo 4-port brake system. To ensure

|

| braking performance and

reliability, the cooling capability is important for the brakes by more air

passing through. Honda has done a magnificent job integrating the Brembo brake

system into Type-R. By looking at the diagram, the brake cooling duct is

designed to let more airflow through the front spoiler directly to the brake

disc cooling, where the heat exchange takes place. The result of an extreme

continuous breaking test from 160 to 0 km/h shows a reduction of temperature at

the front brake pads by about 100 degree. Not only a fade proof nature but also

excellent vapor lock toughness has been achieved. The front and rear aluminium

brake caliper weighs about 2.3kg and 1.3kg respectively. Weight is an important

factor of improving extreme high performance cars.

|

|

|

|